Published Research Removes Excess Fluoride from Drinking Water

"Fluoride removal in batch and column systems using bonechar produced in a top-lit updraft drum gasifier and furnace" has been published in the . The paper is the result of multi-disciplinary research conducted by Civil Engineering Assistant Professor Kyle Shimabuku, Ph.D. and Mechanical Engineering Associate Professor Marc Baumgardner, Ph.D. plus several of their research students.

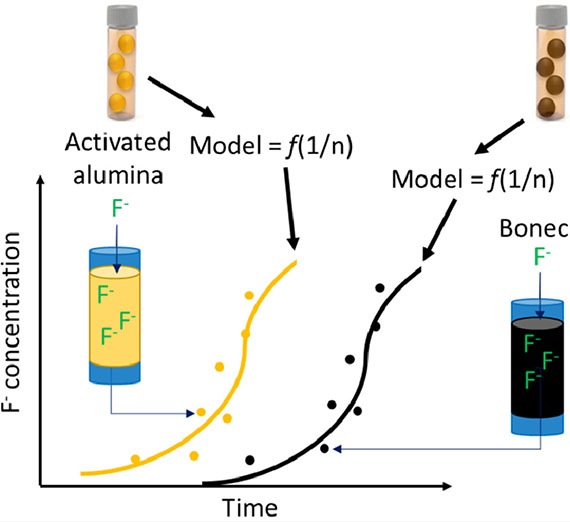

The research explored biochar production conditions using a Top-Lit UpDraft and furnace, then compared performance of their various biochar results. The team then removed fluoride from Spokane municipal water with their biochar adsorbents and the industry standard: activated alumina. They found that their bonechar could outperform activated alumina at a lower cost and easier usage.

Some funding for this project was provided by the U.S. Bureau of Reclamation.

Using forms of biochar for water treatment is the primary focus of Dr. Shimabuku's Environmental Engineering Lab, which is part of the Civil Engineering Department.

Optimizing combustion efficiency is a focus of Dr. Baumgardner's Clean Combustion Lab, which is part of the Mechanical Engineering Department.

Kyle K. Shimabuku, Marc E. Baumgardner, Reggie B. Bahr, Nathan R. Frojelin, Anthony M. Kennedy, Kyle T. Nolan, Nicole E. Stanton, Fluoride removal in batch and column systems using bonechar produced in a top-lit updraft drum gasifier and furnace, Water Research, Volume 244, 2023, 120332, ISSN 0043-1354,

Abstract: Hundreds of millions of people are exposed to excessive levels of fluoride in drinking water, predominately in low-resource communities. Activated alumina is recognized as the best available technology for fluoride removal from drinking water by the United States Environmental Protection Agency, but it has substantial economic and environmental costs. Bonechar is a more environmentally friendly and potentially lower cost alternative adsorbent. Here, fluoride adsorption from groundwater (pH 8.1 ± 0.2) by activated alumina was compared with bonechar primarily produced from bovine bones at peak heating temperatures between 400 and 1100 °C in a modular top-lit updraft drum (TLUD) stove (using a bone-wood mixture) and furnace. TLUD and furnace bonechar produced at peak heating temperatures 650–1000 °C and 400–800 °C, respectively, outperformed activated alumina in batch tests (i.e., required smaller doses to achieve 90% fluoride removal). The impact of using bovine versus swine bones to produce bonechar had a negligible impact on fluoride adsorption. A wide range of peak heating temperatures in the TLUD achieved by varying primary air flow rates and fuel selection (e.g., bone-to-wood mass ratios) produced efficient fluoride adsorbents. This finding demonstrates that a TLUD can be a robust, operationally flexible production system. Fluoride removal by TLUD and furnace bonechars showed strong, negative correlations (R2 ≥0.88) with organic matter content. Bonechar pilot column tests indicated that the mass transfer zone was captured (i.e., immediate fluoride breakthrough was not observed) at an empty bed contact time (EBCT) of 5 min, increasing EBCT to 30 min had a minimal impact on adsorption efficiency, and intermittent operation (3–10 d shut-off periods) decreased effluent fluoride concentrations. Furnace bonechars produced at peak heating temperatures 400–700 °C outperformed activated alumina in pilot columns. Differences in adsorption efficiencies in batch and column tests were associated with the linearity of fluoride adsorption. A theoretical model quantifying adsorption linearity with Freundlich 1/n values was able to predict adsorber performance solely based on batch test data.